Yacht owners: If you’ve owned your yacht for any length of time you may find yourself at a crossroads of whether or not it’s time to start shopping for a new yacht or make necessary repairs to your existing vessel. It’s likely you have been on many memorable trips with friends and family that have … Continue reading “Are you in love with your yacht? When a yacht refit makes sense and how to choose a refitter”

Yacht owners: If you’ve owned your yacht for any length of time you may find yourself at a crossroads of whether or not it’s time to start shopping for a new yacht or make necessary repairs to your existing vessel. It’s likely you have been on many memorable trips with friends and family that have built lasting memories. When does it make sense to do a yacht refit? How do you go about choosing the right yacht refitter to do the job?

There are many things to take into consideration. Most newer yachts are loaded with new technology and systems. While these are great selling points, are these new systems in your best interests? The answer is not so simple. Most of the time a yacht owner or crew members know every inch of you vessel. When presented with a new yacht with new technologies they will find new issues will not be as easily rectified because of lack of knowledge, which can be costly and can certainly rack up lay days at the shipyard while your crew and or contractors learn on your dollar. This is where keeping and refitting you older vessel will be more cost effective in the long run.

When weighing the pros and cons of purchasing a new vessel or moving forward with a refit you’ll have to do the math. Here is an outline to help you get started.

1. Cost: Is your vessel beyond repair? If not, can you afford a refit? A yacht refit can consist of many different variables that may be hidden beneath the superstructure of your yacht.

There may be things happening below the surface that may be missed or will pop up while in the middle of a large refit, so it’s important to choose the right refitter. That leads to part two…

2. Estimates: When choosing the right yacht refitter, it doesn’t hurt to scour the internet looking for reviews of contractors. But your search will not end there! It’s important to get several estimates. The best estimate is not always the cheapest or most cost-effective. A bad refit can certainly cost more in the long run.

3. Planning: Choose a company that can build an estimate by planning the refit from prior refits along with experience. This is a crucial step in the process.

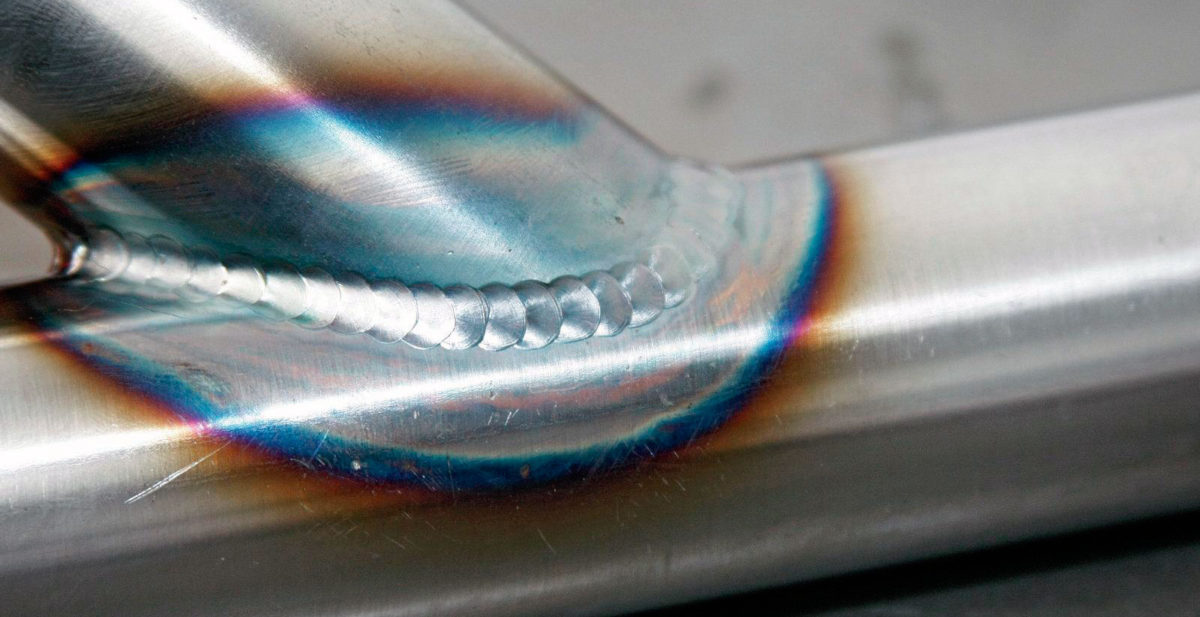

4. Skills: The right yacht refitter will specialize in what they do. Many refit yards hire different sub-contractors that bid on the job, and not to anyone’s surprise the job will go to the lowest bidder. That being said, YOU as the owner of you vessel should have some influence on who is performing your yacht refit. You should be able to feel comfortable with the refitter and not wonder about the final outcome.

5. Job Timeline: Having a good estimated timeline of when your refit will be finished is a good indicator of the quality of the contractor you’re hired. if your contractor cannot give you a timeline, this might be an indicator that they are not the right contractor for the job.

Choosing a company such as Dolfab will ensure that all the steps above are covered. We will walk you through your job from the very inception and do our very best to ensure all issues (obvious and hidden) will be taken into consideration. From the very beginning, we can even video document the entire refit job so there will be no questions that cannot be answered at the time of Commissioning.

Since 1984 Dolfab, Inc. has provided quality work held to the highest standards ensuring your beloved yacht will continue to make memories for you and your family.