How to perform basic boat maintenance and repair on unclassified boats

There are a lot of different types of boats in use today. Boats are generally classified by size and purpose. Most people recognize large commercial barges and trawlers as well as Yachts. Those that are harder to recognize are all the other boats that are considered unclassified.

Unclassified: These are typically smaller boats that are used for personal pleasure such as Bowriders, Cabin cruisers, Deck Boats, Dinghies, Ski Boats, Jet Boats, Multi-Hull Power Boats, Pontoon Boats, Sailboats, Sport fishing boats, Trawlers, and Walkarounds

Smaller boats without classification do not undergo regular surveys and inspections. However, they need every bit as much Boat care and maintenance as any other type of boat.

For the first time boat owner, the care and maintenance of a boat can be a daunting task. Where do you begin? How do you know what to do? How often? Some boat owners turn to Practical boat owner maintenance guides, boat maintenance software apps, boat maintenance software free etc. There are many aids out there to help you determine what needs to be done and when.

What is boat maintenance?

Boat cleaning and maintenance is vital to the safety and functioning of your boat. Properly maintained boats will avoid the damage caused by:

- Corrosion: 90% of corrosion problems on a boat corrode from the inside out due to the lack of access and maintenance. Ventilation is important.

- Contamination and Sediment: The chief problems of mist fuel systems in water intrusion that allow in sediment, which leads to fuel contamination.

While many boaters prefer boat maintenance dyi, there are some tasks that are best left to professionals. Boat maintenance companies offer a Boat maintenance service agreement or boat maintenance contract. Here is an example of a basic boat maintenance contract template http://www.krenzermarine.com/images/pages/service/2016-2017-winterization-form.jpg

How much does boat maintenance cost?

According to an article in Bloom berg personal finance magazine, Yearly boat maintenance costs average roughly 10% of the cost of the boat. For example, a boat that costs $30,000 would have Boat annual maintenance costs of $3,000. That does not include the cost of storing your boat for the winter.

If you are considering having a professional boat repair maintenance company take care f of your boat, they can likely provide you with a Boat maintenance costs guide that will detail their Boat maintenance expenses to let you know whether their fees will fit within your Boat maintenance budget.

Do you need any specialized Boat maintenance tools?

Having the right tools on board your boat will make it easy for you to fix unexpected problems and take care of basic maintenance chores both on and off the water. You should consider putting together a boat maintenance tool kit for yourself in order to handle the boat maintenance basics. You will want to include:

- Adjustable wrenches

- Allen and Hex Key Wrenches

- Chisels

- Duct tape

- Phillips head screwdriver

- Slotted screwdrivers

- Hacksaw

- Hammer

- Hemostats to get into small and tight places.

- Regular vise Grips

- Spark Plug Socket

- Utility Knife

- Vise Grips

- Wire Strippers

- Wire Cutters

- Wire Crimpers

- Boat measuring tools such as calipers, fold out rulers and tape measurer.

- Boat battery maintenance charger

- Boat maintenance accessories like a funnel, drip cups, pads, rags, trash bags,

- Boat oil changer and universal filter wrench

Either uses a traditional tackle style toolbox or a flexible soft side tool bag to store your tools if you don’t have a tool drawer or cabinet on your boat.

How to conduct basic boat maintenance

There are a lot of boat maintenance requirements. You will want to keep a boat maintenance schedule or a boat maintenance calendar so you do not forget what boat maintenance tasks need to be done and when. Typically, you want to pay attention to Boat maintenance procedures as follows:

(1) Spring Start-up or Pre-Season maintenance such as that detailed in this checklist http://nmma.net/assets/cabinets/Cabinet464/7914_DB14_Spring_Startup_Checklist.pdf

- Belts, Cables and hoses: Check all belts, cables and hoses to make sure they fit tightly and are not worn, brittle or cracked.

- Fluid levels: Check to be sure that engine oil power steering fluid, power trim reservoirs and coolant are all filled.

- Fuel System: Check hoses and connections for wearing, brittleness, and cracking and make sure all clamps and fittings are tightly secured. Test the exhaust; ventilation and engine systems go be sure they are operating, as they should.

- Electric System: Check all electrical connections to be sure they are tight and do not have any corrosion. Make sure the battery is charges.

- Propellers and hulls: Check the propeller to be sure it is tightly secured and had no damaged areas. Inspect the hull for blisters or cracks and be sure the drain plus is tightly in place.

- Safety Gear: Check to make sure life jackets, fire extinguishers, carbon monoxide detectors are all in proper working order.

(2) Semi-Annual maintenance such as that detailed in this checklist http://nmma.net/assets/cabinets/Cabinet464/7915_DB14_Semi-Annual_Checklist.pdf

(3) Winterizing or Post-season maintenance such as that detailed in your boat’s owner’s manual.

Boat battery maintenance and charging: Charge your battery pre-season, semi-annually and post-season and test it to be sure it can hold a charge.

Boat bottom maintenance: Regularly inspect the boat bottom for blisters or cracks and cleaning with an environmentally safe cleaning formula will keep the hull in great condition for years to come.

Boat top maintenance:

- Boat canvas maintenance: With all of the water and weather conditions that your boat is exposed to, boat canvas and the vinyl enclosures should be cleaned periodically with mild soapy water and rinsed clear. After drying, use a plastic scratch remover to remove light scratches from the vinyl. The canvas should be treated every two years with Fabric Guard to keep it water repellant.

- Boat canopy maintenance: The boat canopy, also known as the Bimini top, should be cleaned in the same manner as boat canvas.

Boat deck maintenance: Regularly inspect the deck for cracks and clean it with an environmentally safe cleaning formula. Teak boat decking maintenance may require periodic oiling of the teak wood in order to prevent fading and cracking.

Boat diesel maintenance:

Modern diesel engines on a boat contain many electronic controls and some things on your maintenance checklist for the engine should be left to a mechanic or professional. However, there are certain things that a boat owner should be attentive to. Each time your run your boat you should check the boat maintenance fuel level, oil level, coolant level, belt tightness and strainer obstruction. The basic parts of the diesel engine that require maintenance are:

Fuel system: Maintaining your diesel engine’s fuel system is not difficult, but it does require diligence to keep it running smoothly. Before you take your boat out for a spin, always check the fuel and engine and marine oil levels and refill if necessary. At least monthly, you will want to drain the water and sediment form the fuel tank to prevent any debris from entering the fuel system and messing up the engine.

At the end of the season, again drain the fuel tank and replace the fuel filter element. Before you change the oil, it is a good idea to treat the fuel system with a diesel fuel stabilizer and a diesel conditioner and anti-gel. Once you have put in the additives, run the boat long enough for the treated fuel to get into the fuel lines, filters and engines. Then, go fill your tanks and screw down the fill cap so your tank will be free of water.

Every 1000 hours, you should have a professional boat mechanic check the fuel injection timing and the fuel injector spray pattern and, if issues are found, repair or replace the fuel injection system.

Lubrication system: Most recreational boats should have oil and filter change at the end of each season.

Get all of your oil changing materials ready to change out the oil- oil change pump, used oil container, oil-absorbent pads and rags, funnel, new oil and filter and a plastic cup. It is a good idea to lay everything down on a piece of plastic so the boat deck etc. doesn’t get messed up with oil. First, you want to use an oil change pump system that is mounted on a 3.5-gallon tank and has clamped on battery leads and a dipstick tube. Follow the oil change pump system directions to attach it. Remove the dipstick and take the cap off the oil fill. Unscrew the oil filter and break the gasket free. Pump out the old oil into the containers. Wrap the old filter in an absorbent pad and put it in a trash bag. Lubricate the gasket of the new oil filter with fresh oil, fill the filter up and screw it on the engine tightly. Add the new oil in a clean funnel into the oil filter hold. Check it with the dipstick to be sure you don’t overfill it.

Once all the oil change gear is cleared away, start the engine and let it run for a few minutes so you can check for leaks and make sure you have a tight seal.

Cooling system: Most small boats use a freshwater cooling system with a heat exchanger. The freshwater is not really water at all but rather coolant/antifreeze. Every boat owner should do the following to maintain the cooling system properly:

- Check the coolant level before you start the engine.

- Check and clean the seawater strainer for debris every time you run the engine.

- Check the raw water circulation exiting the engine when the engine is running for odd discoloration or evidence of corrosion.

- Every 250 hours or at the end of each season, check and have a professional replace the seawater pump impeller.

- Every year, have a professional replace the cooling system raw water anodes and clean the heat exchanger.

- Every two years, have a professional clean the cooling system seawater passages.

Most boat owners can check, top off and maintain the proper levels of coolant/antifreeze according to the manufacturer’s directions. Cleaning the anodes and heat exchange system and replacing the pump, however, is best left to professionals due to the caustic nature of the chemicals involved and the need for specialized tools that most individuals will not have access to.

Air intake and exhaust systems: Not every marine engine has an air filter, but if it does, the air filter need to be cleaned or replaced every year. Since most are made of foam or paper, this is not a difficult task.

The exhaust system is typically made of cast iron and is subject to rust. Every season, the it should be check by removing the rubber hose that connects the cooling hose to the mixer at the elbow of the exhaust riser and inspecting it for evidence of rust. If you find rust, remove the exhaust riser and clean it. Caution! If you see a big build up of rust on the mounting bolts, hardware and manifold of the engine, don’t attempt to clean yourself but hire a professional to avoid damaging the engine.

Electrical system: The electrical system does not require an extensive amount of maintenance but there are a few things you want to check on periodically to avoid any malfunctions. Before you run your boat, each tine you should check the alarm and warning indicators. Every month, the battery should be checked to be sure the electrolyte level is stable. Additionally, the tension on the alternator V-belt should be adjusted. Every year the wiring connectors and the alternator V-belt should be checked for signs of wear or damage. Every 1000 hours, a professional mechanic should inspect the alternator V-belt and replace it, if necessary

Engine cylinder head and block: Whenever you start your boat, check the water to see if you can see and leakage of fuel, oil or coolant. If you notice anything, turn the boat off and tighten all the nuts and bolts on the engine cylinder, filters and hoses and belts. Restart the engine. If that doesn’t stop the problem, you should see a professional mechanic to determine the cause. Every 1000 hours, you should have a professional adjust the intake/exhaust valve clearance.

Every engine manufacturer recommends a specific maintenance schedule for their engine, which is usually based on hours of engine operation time that has been used or specified time intervals given in months i.e. 3 months, 6 months etc.

- While many of the tasks are the same, small boat engine maintenance is not exactly the same as the boat engine maintenance done for larger boats. It is a good idea to keep boat engine maintenance log so you can track what needs to be done and what has already been done. Here is a boat diesel log excel template as an example. http://mvdirona.com/blog/content/binary/DironaMaintenanceSchedule.xlsx

Boat exterior maintenance: The boat exterior consists of the hull, the boat bottom, the deck and the windows. Generally, regular inspection and cleaning of the boat exterior will prevent erosion or damage of the surface.

Boat hull maintenance:

- Aluminum boat hull maintenance: One of the biggest problems that can occur with an aluminum boat hull is corrosion.

- Fiberglass boat hull maintenance: The biggest problem that can occur with a fiberglass hull is blisters.

- Steel boat hull maintenance: One of the biggest problems that can occur with a steel boat hull is corrosion.

- Wooden boat hull maintenance: One of the biggest problems with a wooden boat hull is rotting and worms.

Boat fender maintenance: Most boat fenders are made of plastic. Regular inspection and cleaning with an environmentally safe cleaner will prevent erosion or damage to the fenders.

Boat fridge maintenance: Just like you would clean, inspect and maintain the refrigerator in your kitchen, you must also clean, inspect and maintain the refrigerator on your boat. Make sure you use an environmentally safe cleaner.

Boat generator maintenance: Prior to using your boat, it is a good idea to inspect and clean the exterior of the generator. Check to be sure the air inlets/outlets are not blocked and the wires/hoses are not worn or damaged.

Then start the generator up and run it for about 30 minutes and look for any leaks or black smoke in the exhaust and listen for weird noises. Turn on all the electrical loads to check to see that the generator can handle the load. Be sure you can start/stop the generator from all control stations on the boat.

At the end of the season, you will want to prepare the generator for boat storage by wipe clean and oiling any parts that could rust, draining the water lift muffler, removing the impeller, draining the oil and replacing if necessary, and disconnecting the battery.

Boat impeller maintenance: Most manufacturers recommend that the cooling water pump impeller be changed out at least every year to avoid engine damage due to a blocked or malfunctioning water cooling system due to worn, cracked or damaged impeller blades. This job is best left to a professional mechanic.

Outboard maintenance: If your boat has an outboard motor, you will want to do some preventative maintenance to keep your motor running smoothly and safely.

- Flush the engine. Always flush out the engine after every use. Just start the engine and let the pump do the flushing.

- Check the water pump system. While the pump is running, put your finger in the water stream. If it does not seem that the flow is very strong, there may be debris in the outflow tube. Shut the engine off and insert a small wire piece in the outflow tube and work it back and forth to clear debris. Restart the engine. If the flow still is not strong, it may mean that a new water pump is needed.

- Run the engine out of fuel. Disconnect the fuel line and let the engine burn off the fuel from the carburetor. This is a perfect time to check for fuel or water leaks and lubricate all the moving parts.

- Drain the tanks at the end of the season and check for fuel-line cracks, worn spots, damage, and tightness of the fuel-line fittings and clamps.

Boat propeller maintenance is essential if you have a stern driven or outboard driven boat. Before you launch your boat, you should inspect the propeller to make sure there are not items attached that would obstruct the proper operation of the propeller. Fishing line can tangle around the propeller shaft prevent the propeller from turning, big nicks or dents can cause the propeller to vibrate and loosen bearings and seals or cause the boat to burn more fuel than it needs to and reduce its performance. During the season, remove the propeller with a deep well socket wrench and liberally apply waterproof grease to the propeller shaft to prevent corrosion. If you notice big impact dents or severely tangled fishing line around the propeller, it is best to have a professional look at the propeller, shaft and gear case and repair any damage.

Boat rudder maintenance: Before you launch your boat, you should inspect the rudder, the rudder shaft and the bearing on dry land for signs of serious wear, rust, cracking or splitting or damage. If you notice anything that does not look right, you should have a professional mechanic look at it. You don’t want to get out on the water and have problems with the steering system.

At least every 5 years, you should have the complete rudder system including the bearings inspected by a professional and either repaired or replaced if issues are found.

Boat throttle maintenance: Your boat should have either a single-lever or twin-lever control system that include cables that transmit signals to the engine and gear case or transmission to control the boat.

Boat toilet maintenance: While your toilet on your board does not require a lot of maintenance, you do not want to skip its maintenance altogether because, over time, they can develop scale deposits in the hoses, channels and valves that cause the toilet to become harder and harder to flush and become calcified and eventually back up. Big mess!

Once a month, pour a pint of white vinegar in the toilet and then give it one flush every 5 minutes about 3 times. Then pump a gallon of fresh water through to flush the lines. Follow that by pouring in ½ cup of mineral oil or marine toilet lubricant and flushing.

Check the hoses for leaks by running a damp cloth over them and smelling for foul odors. Also check the seals around the piston rod to be sure it is tight. Coat the piston rod with a light coating of Teflon grease.

If your toilet smells bad but does not have a leak or just isn’t working right, it may be time to call a professional mechanic to rebuild the toilet.

Maintenance for boat trailer: Don’t neglect the maintenance of your boat trailer. You do not want to have a tire go flat on the highway on your way to the lake. Before you get on the road, run down this basic checklist.

- Are the safety chains crossed and connected to your vehicle?

- Did you pull the trailer tongue jack up, fold it and lock it?

- All of the lug nuts in place and tightened?

- Is the tie-down strap securely in place across the back of the boat?

- Did you test the brakes and the trailer lights and turn signals?

- Does the trailer ball fit snug on the trailer?

- Is the fastener pin secure in the vehicle hitch?

After every use, spray down the trailer with clean water or if you are at a clean water lake, back just the trailer into the lake all the way and then pull it out before you seat the boat on it.

Before the season, it is a good idea to spray the U-bolts, nuts, winch gear, trailer jack and leaf springs with a rust inhibitor. Use some marine grease and a grease gun to lightly lubricate the Boat trailer maintenance bearings on the wheel hubs. Check the brake lines for signs of wear or damage and fill the brake fluid to the proper level.

Don’t forget the Boat trailer hitch maintenance. Check the Trailer ball and fastener pins for rust and signs of wear. Use steel wool to rub away rust and spray with a rust inhibitor.

As the old saying goes, an ounce of prevention is worth a pound of cure. There are a lot of things to do to keep your boat well maintained and if any are neglected, the result could be deadly, in many cases.

A professional boat repair company will be happy to put you on a yearly maintenance contract and take care of all your maintenance needs for you. The added advantage of having professional do it, is that while they are performing the required maintenance, if something is out of the ordinary and requires repair or replacement, they can take care of it right then. The biggest advantage is the time you save. Instead of spending countless hours on maintaining your boat, leave those tasks to the professionals so you can be out on the water fishing or skiing and enjoying your boat. Contact us for more information and customized solutions to your boat maintenance and repair needs.

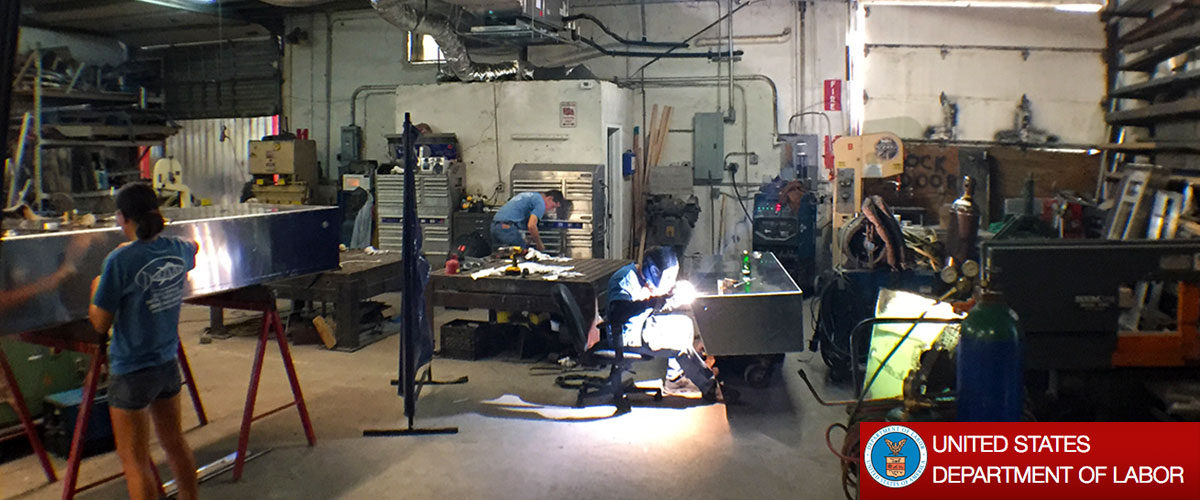

With the ABS, the American Bureau of Shipping, they have their own criteria and standards to work from in from the welding. The welders have to be certified by ABS has to be approved and inspected- and as far as the electrical work, all the mechanical work, everybody there has to be ABS certified… and the material they use… the mills that we get the material from… the alloy, the aluminum, and the stainless… anything we use on the boat has to be- have record and classification, it be from a certified mill, from-sanctioned from the American Bureau of Shipping.

With the ABS, the American Bureau of Shipping, they have their own criteria and standards to work from in from the welding. The welders have to be certified by ABS has to be approved and inspected- and as far as the electrical work, all the mechanical work, everybody there has to be ABS certified… and the material they use… the mills that we get the material from… the alloy, the aluminum, and the stainless… anything we use on the boat has to be- have record and classification, it be from a certified mill, from-sanctioned from the American Bureau of Shipping.