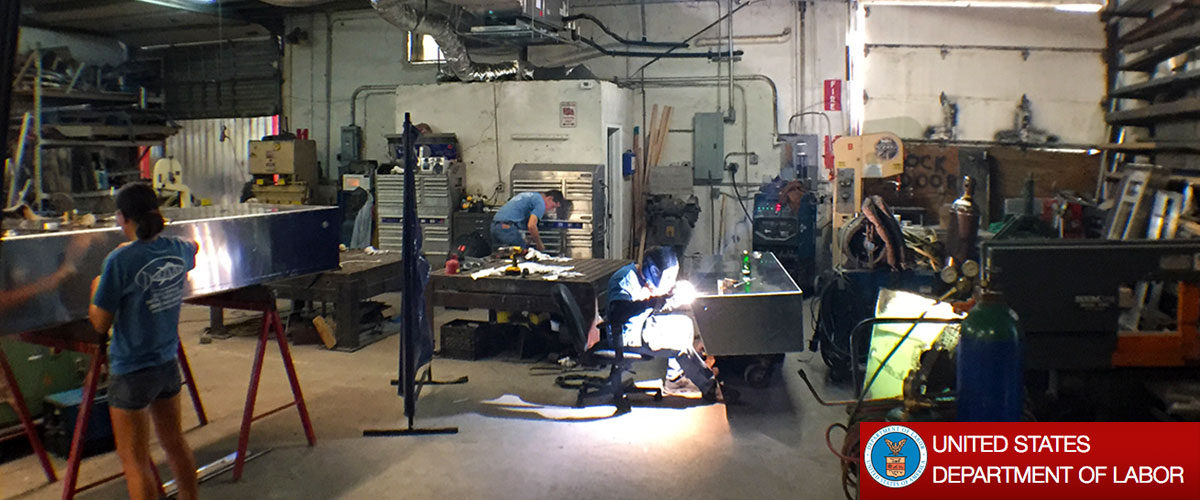

It has been a busy hurricane season in the United States. We’re all still reeling from the impact of Hurricane Harvey in Texas, and now here in Florida we’re getting ready for Hurricane Irma.

There are many resources for preparation checklists and information. Below is a quick rundown of some of the items boaters in particular have to pay attention to, as well as additional links and tools for general preparedness further down below.

For boaters:

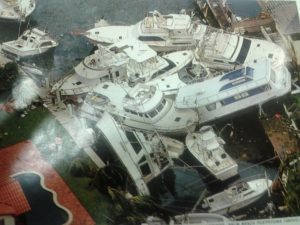

– Move your boat inland if at all possible. As in real estate, location is one of the most (if not THE most) important thing you can do to safeguard your vessel. Try to place your boat in a sheltered area as far from water as possible. Read this article for more information on the importance of boat location during a hurricane.

– Use plenty of duct tape to secure hatches, drawers, cabinets, vents for fuel and water tanks, seams in doors and windows, etc.

– Make sure to have extra lines for your boat and strap it down securely. Check out BoatUS’s article on strapping down your boat during a hurricane.

Other items to have on hand:

– Water for 3 days per person

– Non-perishable items like canned goods, peanut butter, energy bars

– Candles and matches

– Flashlights and extra batteries

– Prescriptions refills

– Toiletry items and a first-aid kit

And other things you might want to do, in addition to putting up shutters:

– Top up the gas in your cars

– Bring toys, bikes, plants, etc indoors

– Get extra cash from the ATM

This list is by no means exhaustive. For more information, checklists, and tips, please visit the links below.

– NOAA Hurricane Center for general preparation. It’s best to have your hurricane supplies on hand well before a storm is on the horizon.

– BoatUS has a terrific section on their website dedicated solely to Hurricane Preparation for Boaters. There is a separate section for every separate thing boat owners need to pay attention to.

– FloridaDisaster.org offers many tools and information for planning and prepping before a natural disaster. Just click here and scroll to the section titled “Be Prepared”.

– For boater-specific checklists, you can visit BoatSafe or Florida’s Department of Environmental Protection. They have a Hurricane Preparedness Plan here and a Boating Hurricane Checklist here.

No one knows how a hurricane is going to turn out, and the best course of action is to be as prepared as possible. Please be sure to start early and finalize all preparations before the storm arrives. Hurricane preparedness must be taken seriously. Stay safe, friends!